Product Category

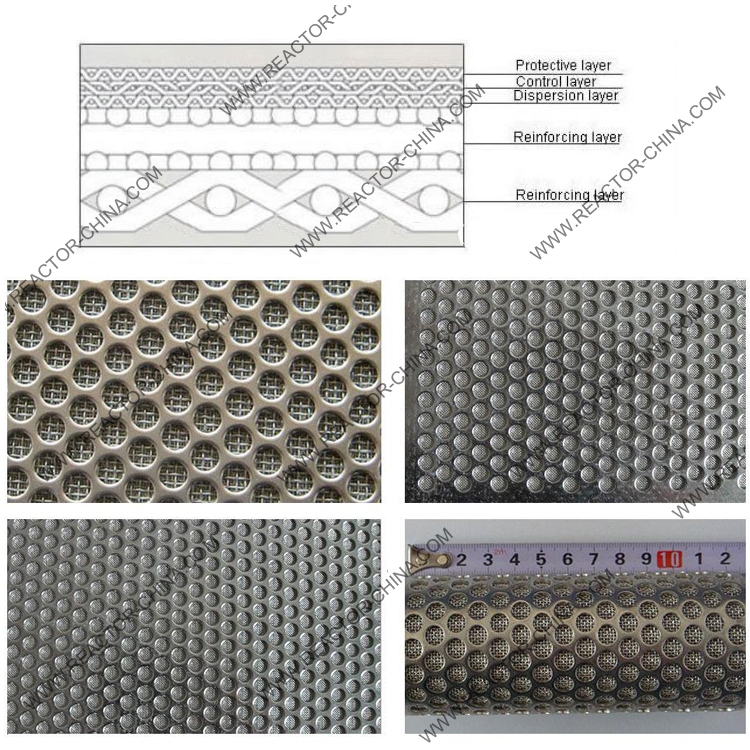

Stainless steel sintered metal-mesh filter

The rolling of the 316L or 304 stainless steel wire by a multi-layer (five layers) stainless steel, which is made by high temperature vacuum sintering and argonarc or plasma welding. The size and distribution of the pores are adjusted by choosing the wire diamter, mesh size and wwaving method of wire mesh.

Properties:

Defined permeability and particle retention

Good mechanical properties

Corrosion resistance

High temperature resistance

Good back flushing performance

No materials shedding and longer service life

Forms and size:

Disks and tube shape can be made. Fitting can be bonded to the porous parts by welding or directly during sintering process. A wide range of well defined pore size distributions from 2um to 200um.

Material: SS304 or 316L

Applications:

Polyester filtration filter

Oil filtration filter

Pharmaceutical bleaching

Food and beverage filtration filter

Chemical products filtration filter

Water and air filtration filter