Product Category

Titanium heat exchanger

Heat exchanger introduction:

Heat exchanger, also called heat transfer machine, is the equipment that can transfer certain heat from the thermal fluid to the cold fluid. It is the essential equipment to achieve the heat exchange and transfer during the production process.

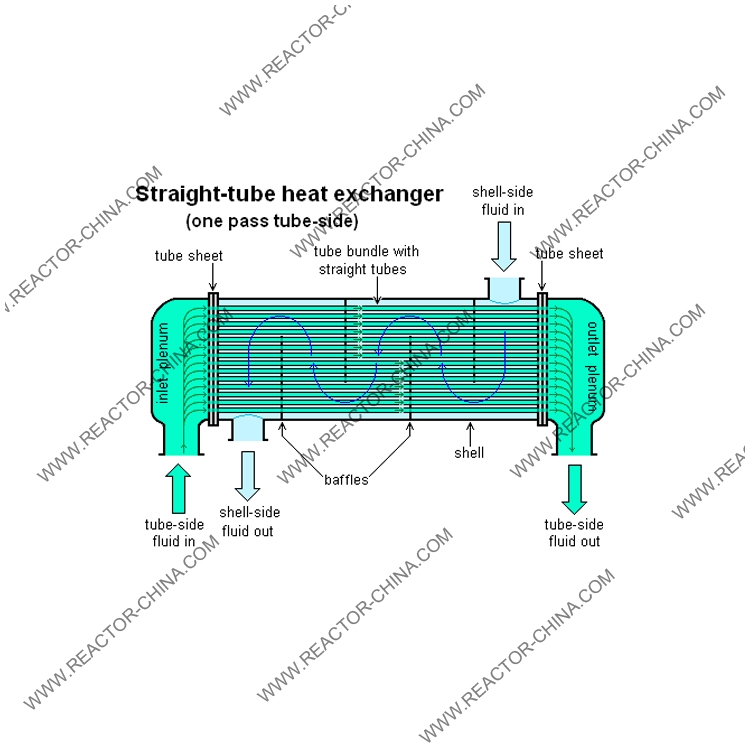

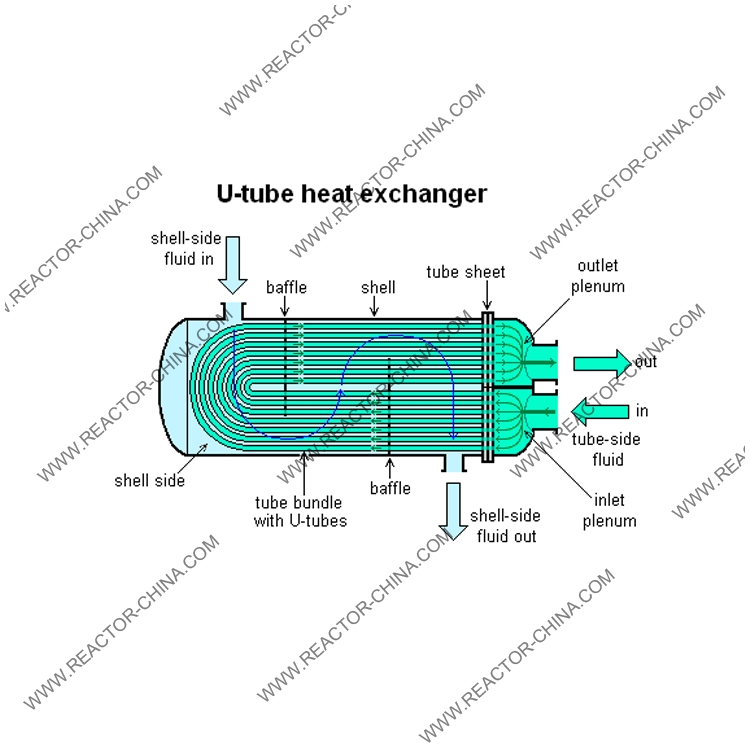

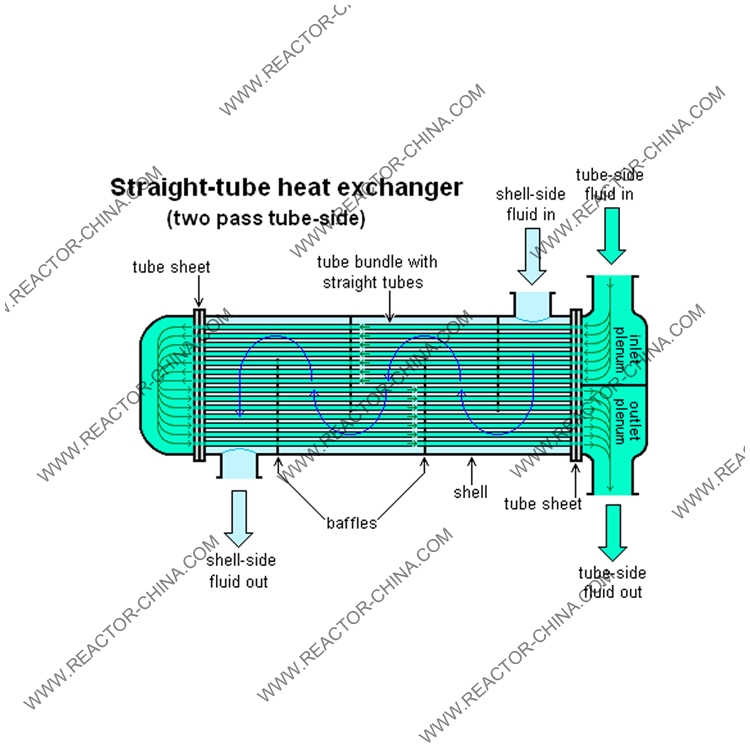

The type of heat exchanger we can produce includes: Spiral-plate heat exchanger, corrugated tube heat exchanger, threaded pipe heat exchanger, fixed tube-sheet exchanger, spiral baffle plate heat exchanger, double-tube plate heat exchanger, fin tubular heat exchanger, float-head heat exchanger, U-tube heat exchanger, stacked heat exchanger, and decompose type heat exchanger etc.

Heat exchange area and pressure can be designed and customized according to customers’ requirements.

the tube heat exchangers which include U type, float-head type, corrugated tube type and so on.

|

Heat exchanger area(M2) |

8 |

30 |

40 |

15×2 |

|

|

Working Pressure(MPa) |

Shell |

0.6 |

0.3 |

0.6 |

-0.1 |

|

Tube |

0.6 |

0.6 |

0.6 |

-0.1 |

|

|

Working Temperature(℃) |

Shell(in/out) |

20/55 |

55-95 |

165 |

120/60 |

|

Tube(in/out) |

220/150 |

164 |

85 |

40/90 |

|

|

Number of Passes |

Shell |

1 |

1 |

2 |

1×2 |

|

Tube |

2 |

2 |

2 |

2×2 |

|

|

Water Test Pressure(MPa) |

Shell |

1.13 |

0.84 |

0.92 |

0.2 |

|

Tube |

1.13 |

0.84 |

0.85 |

0.2 |

|

|

Weight(Kg) |

361 |

1095 |

1442 |

1415 |

|

|

Main Material |

Titanium, nickel, Stainless Steel SUS304/316/316L, Carbon steel.. |

||||

Application:

· Lube oil cooling

· Engine jacket water cooling

· Hydraulic systems

· Molding machines

· Vegetable oil cooling

· Marine applications

· Refrigerant evaporating

· Refrigerant condensing

· Paints and coatings

· Vapor recovery systems